Our marketing team recently spent two exciting days digging deep into the science and testing behind asphalt mixtures at Asphalt Testing Solutions and Engineering (ATS) in Jacksonville, Florida. As a relative newcomer to the asphalt industry, I jumped at the opportunity to attend this immersive training course taught by the renowned Tanya Nash, P.E.

The course kicked off with a brief history of asphalt (Fun fact: Did you know that asphalt has been used to build roads since ancient Babylonian times more than 2000 years BC?!) and an overview of the present-day asphalt industry. We then did a deep dive into asphalt binders and mixtures — touching on testing methods, material specifications and mix design methodologies. We also went through a marketing exercise with ATS’ Molly Berry, which helped us think about our own strengths and weaknesses to identify areas of growth and market opportunities. We also got a crash course in asphalt terminologies, broadening my understanding of the industry.

While the classroom instruction was invaluable, my favorite part was visiting ATS’ labs and getting hands-on experience with the asphalt itself! We tested asphalt binders, prepared sample asphalt cores and even created our own mix design by measuring raw aggregates (aka rocks) used in the mixes. While I love working as a marketing administrator for Polyco, I may have found my true calling working in the “Rock Room!” It was eye-opening to learn so much about the science underpinning high-performance modified asphalts like Polyco’s SigmaBond.

Beyond the technical knowledge, I was incredibly impressed by the ATS team’s passion and expertise. From the guys who handle hot asphalt and sort aggregate to the technicians and engineers who operate testing equipment and measure binder performance — everyone we met truly brought the course material to life. These folks live and breathe asphalt testing and engineering. By patiently answering our many, many questions, I really got to experience their love of the industry and the work they do.

The ATS Asphalt Mixture Training was an amazingly immersive experience that let me dive feet-first into the world of asphalt science and testing. I came away with a much deeper understanding and appreciation for the work we do in manufacturing high-performance, sustainable asphalt products that enable the use of more recycled materials. I’m proud and honored to work in such an essential industry. I look forward to attending more trainings to expand my knowledge as we push the asphalt industry from black to green!

As the Director of Technical Sales at Polyco, I’m excited to share highlights from a recent collaboration with Skip Brown, a seasoned figure in pavement consulting and Dr. Peter Sebaaly, Director of the Western Regional Superpave Center at the University of Nevada, Reno. With a career spanning over four decades in the pavement industry, I’ve been lucky enough to witness uncounted innovations. The article Skip, Dr. Sebaaly and I wrote delves into one of the most groundbreaking — Polyco’s SigmaBond. In the article, we explore the evolution of rubberized binders and how SigmaBond is revolutionizing the landscape. Read on for some of the highlights of the article, which was recently published in a newsletter by the California Pavement Preservation Center (CP2C) of Cal State Chico.

Over the past 50 years, California’s pavement industry has witnessed the extraordinary evolution of rubberized asphalt binders. Traditionally, asphalt rubber (AR) methods involved blending ground tire rubber into the base binder at the hot plant. However, advancements have introduced the terminal blend approach, resulting in a rubber-modified binder (RMB). This innovative method allows for greater flexibility and convenience in handling rubberized asphalt.

RMBs like Polyco’s SigmaBond offer key advantages over traditional AR binders, especially for smaller paving jobs. One notable benefit is storability – RMB can be produced at a terminal, stored in tanks and shipped to multiple hot plants. This eliminates the need for special blending equipment at individual plants, making it a cost-effective and efficient solution. RMB formulations are versatile, applicable to both gap-graded and dense-graded hot mix asphalt, and can be customized to meet various performance grades.

As a sustainable solution, SigmaBond allows high RAP usage while delivering superior cracking resistance. Research from the University of Nevada, Reno (UNR) has validated SigmaBond’s performance in dense-graded rubber-modified hot mix asphalt (RHMA), showing excellent resistance to reflective cracking: 5-6 times better than unmodified mixes.

Cracking resistance isn’t all SigmaBond offers. The mixes evaluated in the UNR study, containing 25% recycled asphalt pavement (RAP), also demonstrated equivalent or improved moisture resistance, fatigue life and rutting resistance compared to conventional mixtures. These findings support the recommendation of SigmaBond RMB for dense-graded rubberized overlays on projects of all sizes.

Recent projects in California have put SigmaBond to the test, and the results have only reinforced these benefits. Contractors paving 2-inch dense-graded rubberized overlays in Rancho Murieta, Los Lagos and Stockton achieved excellent in-place density, workability and uniform surface textures that outperformed conventional mixes. The photos below show the highly uniform and tight texture of the finished surfaces.

As a pioneer in sustainable asphalt modifiers, Polyco’s SigmaBond RMB is driving the future of rubberized binders and circular paving practices. SigmaBond’s ability to be easily batched and stored allows its advantages to extend to projects of any size, from major highways to private parking lots. By enabling high recycled material usage while delivering outstanding cracking and aging resistance, Polyco empowers contractors and agencies to construct longer-lasting, lower-maintenance pavements.

SigmaBond is just the beginning of Polyco’s innovative asphalt paving solutions. I encourage you to explore our website, meet with us at conferences and other events and reach out to learn more about all the exciting ways we can shift the asphalt industry from black to green together.

In our ongoing commitment to sustainable solutions for the paving industry, we’re diving deep into the groundbreaking possibilities of SigmaBond — our high-performing asphalt material made from waste tire rubber. Building upon our last blog post, “Harmonizing the Hallmarks of Sustainable Pavements,” where we looked at perpetual pavements and balanced mix design, this installment will dig deep into how SigmaBond signals a new era of sustainability in asphalt paving construction.

Use More Recycled Materials

SigmaBond is more pliable and easily blends with recycled materials due to our patented Rapid Digestion Process™, which completely liquifies end-of-life tires and asphalt into a homogeneous concentrate. SigmaBond’s unique composition not only enables contractors to use up to 50% tire rubber in their terminal blend mixes but also allows up to 35% recycled asphalt pavement (RAP) and recycled asphalt shingles (RAS).

SigmaBond’s superior workability also allows contractors to achieve proper pavement density and compaction. Furthermore, SigmaBond contains no tire rubber particles that could contaminate unprocessed RAP. This improved constructability pushes the threshold of recycled content for quality pavement construction, reducing the need to source virgin binder and lowering overall material costs.

Close the Sustainability Loop

According to a report from NAPA, incorporating higher levels of recycled materials in asphalt mixes can significantly reduce landfill waste — by as much as 34%.1 This practice also decreases the demand for virgin materials, creating a regenerative pavement lifecycle that minimizes resource extraction and improves profitability.2

At every step of the paving lifecycle, SigmaBond diminishes the asphalt waste stream and helps close the sustainability loop. We’ve already diverted over 1.5 million tires from landfills since SigmaBond went into production, and will continually innovate to further reduce waste. With a higher percentage of binder containing recycled materials in the mix, the environmentally harmful process of sourcing virgin materials is naturally reduced. Repeatedly upcycling asphalt pavements, shingles and waste tire rubber moves us closer to a circular economy that enhances profits by lowering the material cost of road construction.

Lower Carbon Footprint

The asphalt manufacturing process is energy-intensive, involving the heating and mixing of aggregates and bitumen at high temperatures. By reducing the need for new asphalt production and utilizing recycled materials like waste tire rubber, RAP and RAS, SigmaBond helps curb the carbon emissions and fossil fuel consumption tied to this process.

Furthermore, by engineering roads that last longer, SigmaBond minimizes the energy and resources required for pavement maintenance. When a pavement’s lifespan is extended, repairs, resurfacing and reconstruction are less frequent. Increasing the time between these interventions reduces the environmental impact associated with pavement upkeep. By making asphalt and emulsions that endure, we contribute to a healthier environment and a lower carbon footprint for everyone.

Looking Ahead

As we continue our journey from “Black to Green,” there’s an exciting revelation on the horizon. Stay tuned for our upcoming blog post, when we’ll unveil SigmaBond’s Environmental Product Declaration (EPD). This groundbreaking release will quantify SigmaBond’s contribution to reducing CO2 emissions, provide data-driven insights into its environmental benefits, and help paving contractors and road agencies make informed decisions about their material choices and sustainability goals.

SigmaBond is more than an innovative asphalt material; it’s a sustainability powerhouse. Join Polyco in embracing the future of sustainable infrastructure, where SigmaBond pushes the limits, creating high-performing and environmentally responsible solutions for the asphalt pavement industry.

In many sectors, including the asphalt pavement industry, sustainable materials are coming into play and are at the top of everyone’s agenda. Recycled asphalt pavement and shingles (RAP/RAS), waste tire rubber (WTR), plastics, glass – many scrap products find viable end uses in pavements. But focusing on materials alone is not enough to achieve truly sustainable pavements. It’s also about design and process.

With SigmaBond — a truly liquefied rubber asphalt using patented Rapid Digestion Process™ — Polyco is eager to pave toward a new era for the industry, where mix producers, paving contractors and agencies can realize complete sustainability in their road and highway projects.

Eco-consciousness, long-term performance, efficient production and construction, and cost savings are the hallmarks of a sustainable pavement — and, by marrying new innovations with tried-and-true methods, there are ways to achieve them all in a single project.

Perpetual Pavements: Built to last

One potential solution to achieving pavement sustainability is Perpetual Pavements. The Asphalt Pavement Alliance (APA) defines Perpetual Pavement as “an asphalt pavement designed and built to last longer than 50 years without requiring major structural rehabilitation or reconstruction and needing only periodic surface renewal in response to distresses confined to the top of the pavement.”1

According to research, Perpetual Pavements have a variety of positive attributes. They eliminate reconstruction costs at the end of a pavement’s structural capacity, lower rehabilitation-induced user-delay costs, reduce excessive use of non-renewable resources, such as aggregates and asphalt binder; diminish energy costs while the pavement is in use, and reduce the life-cycle costs of the pavement network.2

However, as with any design approach, there are challenges. First, the upfront costs incurred by intense subgrade work and soil stabilization, longer periods of traffic interruption during the initial build, and the amount of material needed for what is typically a 25 to 30 percent thicker pavement than the standard.

In addition, Perpetual Pavements are limited in how much recycled materials they can utilize. For example, states only allow WTR in the wearing course, or top layer, of a Perpetual Pavement. Fortunately, innovations like SigmaBond asphalt binder are showing that contractors can achieve dense compaction with the use of more recycled materials, such as WTR, in the base and intermediate pavement layers.

At the NCAT Test Track, structural test research is underway on sections where recycled plastics, WTR, and synthetic fiber are utilized in different mixes. The test sections will be subjected to accelerated traffic loading over a two-year period, and the structural response and pavement performance of those sections will be monitored.3

Striking the Balance

Balanced mix design (BMD) is also trailblazing as a sustainable solution. A volumetric mix design that’s keen on performance, BMD gives contractors more leeway in the types of materials they use – as long as the final result is a balance of performance between rutting and cracking.

With BMD, contractors are finding they can save money and maintain quality by using more recycled materials. Workability and density are further improved when technologies such as SigmaBond are incorporated into a BMD.

While there are cost savings with regard to materials and long-term maintenance, there is the expense of the design work and laboratory testing. With BMD, you are essentially creating a custom mix from scratch. Mix designers have to assess local materials, binders, and additives and the combinations thereof to forecast expected resistance to distresses at the lowest cost.4

Methodologies for Determining Pavement Sustainability

Many agencies are turning to life-cycle cost analysis (LCCA) for evaluating the long-term economic viability of pavement designs. In addition to initial construction costs, “an LCCA also considers future costs such as maintenance, rehabilitation and sometimes user costs, all of which are converted into present dollars (called net present value or cost).”5

Often confused with LCCA, a Life-Cycle Assessment (LCA) is different in that it specifically quantifies the environmental impacts over the pavement’s full life cycle, including impacts that occur throughout the supply chain.6 To encourage consistency and adoption of pavement LCAs, the Federal Highway Administration has developed an LCA framework specific to pavements which provides technical guidance on the approach.

Used together, LCAs and LCCAs can truly vet a pavement for the long haul and illuminate the best project overall approach to a roadway project.

We at Polyco look forward to being part of the long haul in the asphalt pavement industry, especially with forward-thinking products such as SigmaBond, the environmental benefits of which we will explore in our next post.

- https://www.driveasphalt.org/uploads/documents/Perpetual_Pavement_Synthesis.pdf ↩︎

- Timm, D.H., & D.E. Newcomb (2006). Perpetual Pavement Design for Flexible Pavements in the US. International Journal of Pavement Engineering, Vol. 7, No. 2, pp. 111–119. doi:10.1080/10298430600619182 ↩︎

- https://eng.auburn.edu/research/centers/ncat/research/newsletters/spring2022.pdf ↩︎

- https://www.eng.auburn.edu/research/centers/ncat/education/bmd.html ↩︎

- https://www.eng.auburn.edu/research/centers/ncat/newsroom/2021-spring/lcca.html#:~:text=An%20LCCA%20is%20a%20process,the%20best%20long%2Dterm%20value. ↩︎

- https://www.fhwa.dot.gov/pavement/sustainability/how.cfm ↩︎

Polyco is delighted to announce that Bob Rivers is coming on board as the new Director of Technical Sales for the West of the Rockies region. With over 40 years working in asphalt paving and roofing, Bob brings a wealth of industry experience to his new role. We sat down with Bob to learn more about his background, his journey to joining Polyco, and what he’s looking forward to.

Can you share a little about your background in the pavement industry?

I started way back in 1981 down in Southern California at an independent refining company that produced the complete gamut of petroleum products from fuels to asphalt. I didn’t like the tedious rotating shifts very much, so I went into the laboratory as a quality control tech for a year, testing aviation and automotive fuels, paving and roofing asphalts. I transferred to R&D for a more flexible schedule and went back to school. This role exposed me to all the nuances of the Dark Side of petroleum science — emulsions, rejuvenation agents, oxidized roofing asphalts, felt saturants, bunker fuels, printing inks and more.

Basically, the R&D team enabled the company to make consistent, finished product formulations from a changing refinery crude charge. Much like today’s Polyco lab folks continue to do now. Some things never seem to change. Same challenges, different day!

How did you first get connected with Polyco?

I met Tom Nichols in Stockton, CA in the 1980s when I was marketing the base asphalt for modified roofing products there. Even then, Tom had big ideas and aspirations for entrepreneurial success. We kept in touch through the years, and in 2014, I joined AST as a consultant, helping to market and sell PG asphalt and SigmaBond in California, Arizona and Nevada.

I’ve been in and around the asphalt game for over 40 years now and over 20 in PG-TR development sales. The SigmaBond technology really intrigued me from the start. Many other TR startups promised everything but could not deliver the goods. It is exciting to see the innovation and new technologies we are developing. Unlike other rubber modification processes that degrade the properties and performance when adding more ground rubber, SigmaBond keeps improving the properties at higher rubber dosages. It’s a game-changer, truly unique, and that got me hooked. As pavement experts and academia have said, SigmaBond PG-TR is the future of TR asphalt binder specifications.

As the new sales and marketing lead out West, what’s got you most excited?

Our biggest challenge now is going to be making enough SigmaBond to satisfy the demand we’re seeing! More and more states and agencies are looking to mandate high recycled rubber contents in their asphalt mixes for sustainability. With SigmaBond, we can finally give them those high rubber loads without compromising the pavement performance. That’s been the big issue holding the other technologies back.

Polyco is pioneering the future for higher recycled rubber contents and more sustainable asphalt mixes with SigmaBond. We’ve got a really remarkable opportunity to promote greater sustainability through more recycled rubber while also delivering better-performing asphalt pavements. Polyco has some awesome products, and I’m thrilled to be partnering with Polyco’s technical team to communicate the SigmaBond PG-TR benefits across the West.

Tell us a little about your life outside of work.

While the asphalt industry has been my career passion for over 40 years now, my greatest joys come from life outside of work with my family. I’ve been blessed with a sweetheart of a wife, Lili, for 41 years and three months so far. We’ve got three of the best children and their spouses that you could ever wish for, and they’ve given us four beautiful grandkids. We’re lucky enough to live near the whole family, and watching those little ones grow up is a priceless gift. Though, I will say… It’s great to see their headlights coming up the driveway, but it’s also a relief to see the tail lights when they’re leaving. They certainly have a lot of energy!! Without a doubt, we’ve been blessed!

Lili and I have a couple of mischievous, small but mighty dachshund-chihuahua mixes that keep us on our toes.

After 10 years of my AST consulting internship and now, I am finally a Polyco employee. I look forward to continuing to collaborate with all my new official co-workers. Again, and most seriously, I am blessed!

It’s what’s inside that counts. The quality of a shingle is only as good as the materials it’s composed of — and shingle manufacturers have been put on notice. More accountability is being demanded of the roofing industry, with an emphasis on expanding sustainability measures.

For more than two decades, our roofing partners have relied on our expertise to give them a strategic advantage in the evolving asphalt shingle market. With sustainability at our core, we are helping manufacturers meet demands today while looking toward the future.

Use more recycled materials

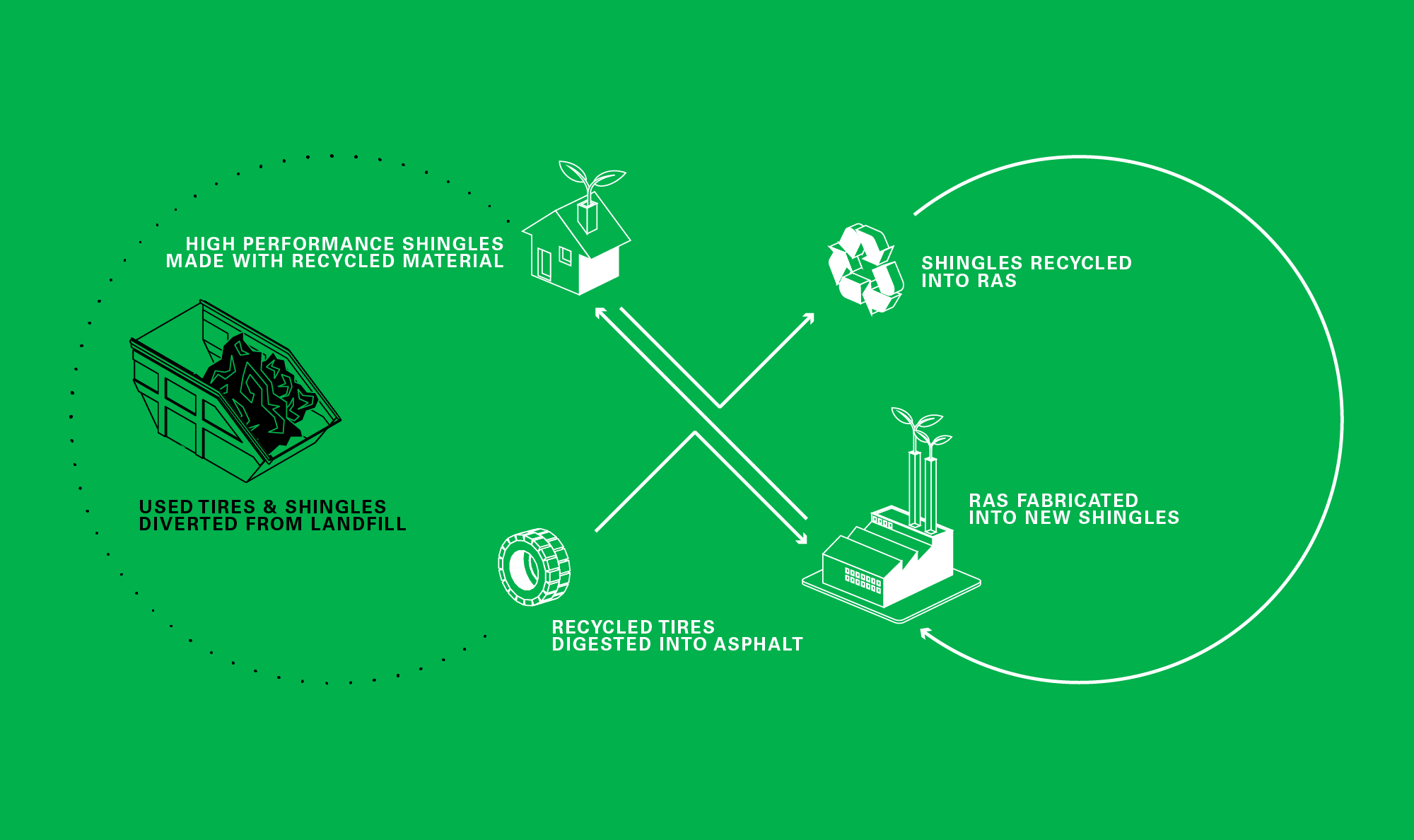

There are 41 million scrap tires that end up in landfills every year, according to a report by the U.S. Tire Manufacturers Association. To combat this wasteful problem, we developed the Rapid Digestion Process™. Our patented technology completely liquefies scrap tire rubber and combines the resulting concentrate with asphalt to create performance-enhancing additives. By enabling up to 50% tire rubber in the mix, virtually every layer of a shingle could contain more recycled materials.

Close the loop in the roofing lifecycle

As more manufacturers are taking asphalt shingle recycling into their own hands, RDP can help reduce the burden. When it’s time to replace a roof, the recovered asphalt shingles can be remanufactured with sealants, adhesives and coatings containing liquefied rubber. Using modified shingles made from RAS with waste tires opens up possibilities within a circular economy and further closes the loop in the roofing lifecycle.

Construct more durable shingles

In many regions across the country, sturdy shingles are more than a nice-to-have — they are a requirement. This is especially true for states like Florida, where shingles must be able to withstand the uplift from Category 5 hurricane-force winds. Our roofing solutions have been tested to reduce blow off and resist dents/ridges, tears and granule loss. In fact, many of our roofing partners have received excellent hail impact ratings from the Insurance Institute for Business & Home Safety (IBHS). The measurable performance is a testament to the quality we deliver.

Extend the life of roofs

Engineering longer-lasting asphalt shingles leads to a longer-lasting roof — which benefits consumers, builders and manufacturers. Addressing problems under warranty are costly for contractors and manufacturers, not to mention a hassle for property owners who have to live under a failed roof. By extending the use life of modified shingles, roofs don’t need to be replaced as often — which diverts waste from landfills.

While our roofing partners have taken great strides to stay ahead of the curve, there is much on the horizon. Sustainability will continue to take precedence — with an increasing focus on Environmental Product Declarations (EPDs), LEED (Leadership in Energy and Environmental Design) certifications and reducing our overall environmental impact. As we continue to keep a pulse on the roofing industry, we will push forward with innovations that meet and exceed demands.

The greatest innovations often have the most humble beginnings. So is the story of the use of waste tire rubber in asphalt pavements. Charlie McDonald – dubbed the father of asphalt rubber1 – pioneered this concept more than 70 years ago.

McDonald’s camping trailer was leaking, and he needed a flexible material to effectively patch and seal.2 His workaround – formulated with scrap tire rubber – served as the basis for a pothole application developed later in his career as an engineer for the City of Phoenix, Arizona.

In the 1970s and 80s, asphalt mix producers began adding large-sized recycled rubber to hot mix asphalt (HMA). However, roads paved with this early rubberized asphalt showed increased levels of failure because of mix design problems, including “insufficient binder, no production heating control, no dwell time control for produced mixes, compaction issues, [and] material handling issues.”3

Advancing the performance potential of recycled tire rubber

Forty-one million tires end up in landfills every year in the U.S.4 It is estimated that about 17% of the scrap tires produced in the U.S. in 2017 were used in modified asphalt binders.5 While that figure is encouraging, more needs to be done to upcycle the resources that are literally trashed.

Innovations, such as our patented Rapid Digestion Process™, have helped push the needle in our industry. Through RDP, end-of-life tires are liquefied and blended with asphalt to create custom asphalt formulations – ones that include up to 50% tire rubber.

States ahead of the curve

California and Texas, along with Arizona and others, have encouraged the practice of increasing percentages of tire rubber in pavements. At this time, Texas allows up to 20% TR while California allows 18-22%. In fact, approximately 31% of all HMA mixes placed in California by the end of 2010 were rubberized HMA.6 And, in Arizona, all high-volume highways have been surfaced with asphalt rubber open-graded friction course.7

Research in these states have confirmed the performance potential of using waste tire rubber with modified asphalt. California Department of Transportation (Caltrans) engineers reviewed the performance of over 100 recycled asphalt concrete (RAC) pavement projects in California and 41 Arizona DOT projects. Their study found that the progress of distresses in RAC pavements was much slower than that of structurally equivalent dense-graded asphalt concrete pavements.

A study conducted for the Texas DOT in 2001 stated that “all asphalt rubber Porous Friction Course (PFC) projects are exhibiting excellent performance properties. Resistance to cracking and raveling in asphalt rubber PFC is particularly impressive. From [a] cost and benefits standpoint, PFC represents the best application for asphalt rubber.”8 In yet another Texas study, pavement evaluation results indicated that rubber modified HMA projects “had significantly better cracking resistance than conventional HMA.”9

A focus on life cycle cost analysis is key to progress

Of the state DOTs that do not allow waste tire rubber in asphalt mixes, 61% cited the higher cost as the main reason for not using it. However, a life cycle cost analysis indicated that the widespread use of asphalt rubber has been cost-effective in Arizona and California.10

Many states are collecting performance data to validate taking the leap. About two years ago, Oklahoma, a state that does not currently allow waste tire rubber in asphalt mixes, conducted a survey of rubberized asphalt roads that were put down in the 1970s and 80s and was impressed with the long-term performance. As a result, discussions about recycling and green technologies have increased at the state’s DOT.

With further use, modification and study, we are confident that recycled asphalt pavements (especially those using waste tire rubber) will become more widely adopted. By pushing waste tire rubber percentages in mixes — and the limits of pavement performance — we can truly enter the next phase of a greener asphalt industry. In our upcoming post, we’ll discuss sustainable pavement designs and their impact on life cycle cost. Stay tuned.

- https://www.rubberpavements.org/RPA_News/2011/201110_Father_of_Asphalt_Rubber_Article.pdf ↩︎

- HISTORY – Rubber Pavements Association ↩︎

- Technical Challenges of Utilizing Ground Tire Rubber in Asphalt Pavements in the United States – PMC (nih.gov) ↩︎

- PowerPoint Presentation (ustires.org) ↩︎

- Baumgardner G., Hand A.J., Aschenbrener T.B. Resource Responsible Use of Recycled Tire Rubber in Asphalt Pavements. U.S. Department of Transportation, Federal Highway Administration, Office of Preconstruction, Construction and Pavements; Washington, DC, USA: 2020. p. 41. Report No. FHWA-HIF-20-043. ↩︎

- Zhou H., Sri H., Vacura P. Caltrans use of scrap tires in asphalt rubber products: A comprehensive review. J. Traff. Transp. Eng. 2014;1:39–48. doi: 10.1016/S2095-7564(15)30087-8 ↩︎

- Shu X., Huang B. Recycling of waste tire rubber in asphalt and Portland cement concrete: An overview. Constr. Build. Mater. 2014;67:217–224. doi: 10.1016/j.conbuildmat.2013.11.027. ↩︎

- Tahmoressi M. Evaluation of Asphalt Rubber Pavements in Texas. PaveTex Engineering and Testing, Inc.; Dripping Springs, TX, USA: 2001. ↩︎

- Freeman T., Pinchett D., Haobo R., Spiegelman C. Analysis and Treatment Recommendations from the Supplemental Maintenance Effectiveness Research Program (SMERP) Texas Transportation Institute; College Station, TX, USA: 2002. ↩︎

- Hicks R.G., Epps J.A. Life cycle cost analysis of asphalt-rubber paving materials; Proceedings of the 1st World of Asphalt Pavements, International Conference; Sydney, NSW, Australia. 2 July 2000. ↩︎

To me, building a sustainable infrastructure is a moral obligation. For the foreseeable future, humans will need roofs for shelter and roads for transportation. Asphalt is a core (albeit overlooked) ingredient in both instances. However, the general public has a narrow view of what asphalt is, how it’s used, and what goes in it. I see this as an educational opportunity to unpack the versatility of this material and how it can advance sustainable practices that power a circular economy.

At Polyco, the path to sustainability has evolved over time but always with the same goal in mind: to reduce our environmental footprint by manufacturing products with zero waste. We invested in this mindset through the development of our proprietary Rapid Digestion Process™ (RDP), which breaks down end-of-life rubber tires into a liquefied state. From this process, we developed a performance-enhancing asphalt additive, SigmaBond, that can be blended to create custom asphalt formulations for use in multiple applications. In addition to upcycling tires, SigmaBond further enhances sustainability by enabling the use of more recycled materials (such as recycled asphalt pavements and recycled asphalt shingles) in asphalt mixes, reducing the need to source virgin materials and crude oil. Moreover, SigmaBond’s performance-enhancing qualities extend the lifespan and usability of roads and roofs so they don’t have to be repaired or replaced as often.

Solving the global waste problem is an issue that is too big to ignore. Reusing end-of-life tires in roads and roofs is a step in the right direction. It’s an innovative, clean way to divert rubber tires from landfills or prevent them from being burned for fuel. But our journey to sustainability doesn’t stop there. We still have a long road ahead of us to become a truly green industry within a circular economy. There are so many other materials to experiment with, new processes to try and technologies to deploy that haven’t even been conceived yet. As advancements are made, Polyco will continue to adapt alongside them until we have completely eliminated waste. It’s a lofty goal but one that is necessary to ensure our future is built on sustainable infrastructure.

Polyco’s Supply Chain Manager, Kaylea LaBee, is a dedicated problem-solver who thrives on new challenges. Starting as an assistant in 2014, Kaylea moved into customer service before recently transitioning to head up Polyco’s supply chain operations. We spoke with her about her evolving career, the excitement of bringing a fresh perspective to the field, and her vision for greener production practices.

What does a typical day look like at Polyco now that you’ve taken on a new role?

I’m our supply chain manager now, so I keep an eye on everything that comes up on the supply side. Every morning, I’m responding to emails, placing orders with raw material vendors, providing forecasts, securing logistics, and monitoring markets for pricing trends. It keeps me on my toes! I’m also getting another degree—this one in supply chain management from Western Governors University—so I’m pretty busy these days.

What do you like most about working at Polyco?

The people! We’re a tight-knit group, and I have a good relationship with team members at all levels. Being able to joke around and have some laughs throughout stressful days makes work really enjoyable. I’m grateful for the support I’ve had from everyone in transitioning to this new position.

What excites you most about the future of your role and the asphalt industry?

I’m seeing the industry focus more on sustainability and green initiatives. My generation cares deeply about environmental impact, so I’m excited that I get to help develop cleaner technologies and production methods with Polyco. Things like finding uses for recycled tires align really well with my values. I’m also making great contacts at industry conferences and traveling more in my new role. Growing my network and seeing operations firsthand is incredibly valuable.

Why is sustainability important for Polyco?

The world is shifting toward more eco-friendly options across industries. Polyco demonstrates care for the planet’s future by developing quality, sustainable products. I know we have a lot of staff with children who want to build a cleaner world for the next generation. Our commitment to reducing waste makes me proud to work here.

What do you love to do outside of work these days?

Between work, school, volunteering at the local animal shelter, and spending time with my boyfriend, my free time is really limited! But I treasure weekends relaxing with my dog Ophelia, hiking, and trying new things. My boyfriend recently got me into disc golf, and I’ve been trying my hand at old-fashioned golf-golf, too! When I can find a quiet morning, I like listening to music while watering my 50 (!) houseplants. Botany is definitely a lifelong passion for me. Simple joys!

As more DOT specifications call for increased percentages of recycled materials in asphalt hot mix, many still need to be convinced about the performance of pavements paved with RAP and/or RAS. Additionally, there’s confusion over the environmental and financial impact of using recycled materials. These are all valid concerns.

However, using RAP and RAS alone is not the answer. We’ll explore how you CAN achieve better performance, sustainability and cost savings with RAP/RAS hot mixes using a performance grade binder.

Performance

A study by the University of Texas, El Paso (UTEP) evaluated mix designs, design processes and guidelines to identify weaknesses and strengths of balanced mix designs involving RAP, RAS and other additives. According to Soheil Nazarian, Ph.D. — a Civil Engineering Professor at UTEP and the lead researcher on this project — adding more binder enables a more flexible mix that doesn’t crack as easily.

This report by NAPA echoes Dr. Nazarian’s sentiment, stating that “high RAP/RAS mixtures can be designed to have better performance than virgin mixtures when a proper mix design approach (such as the balanced mix design method) is employed.”

We’ve seen many real-world examples in which roads paved with RAP and/or RAS perform the same, if not better, than standard-grade asphalt when a PG binder is added to the mix.

Sustainability

The environmental impact of upcycling pavements and shingles is felt both upstream and downstream in the asphalt supply chain. Using more recycled materials in mix designs not only diverts waste from landfills (up to 34% of landfill space, according to the NAPA report) but also reduces the need to source virgin materials — enabling a pavement lifecycle that is truly regenerative.

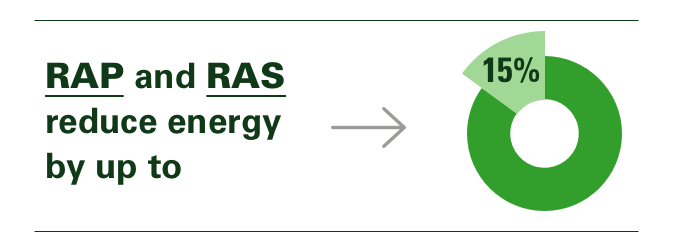

Additionally, that same report claims that RAP and RAS reduce energy by up to 15% — which is key for companies looking to lower their carbon footprint and adhere to EPDs.

At the same time, by engineering roads that last longer, we are naturally reducing the energy and waste materials required to maintain pavements.

Cost Savings

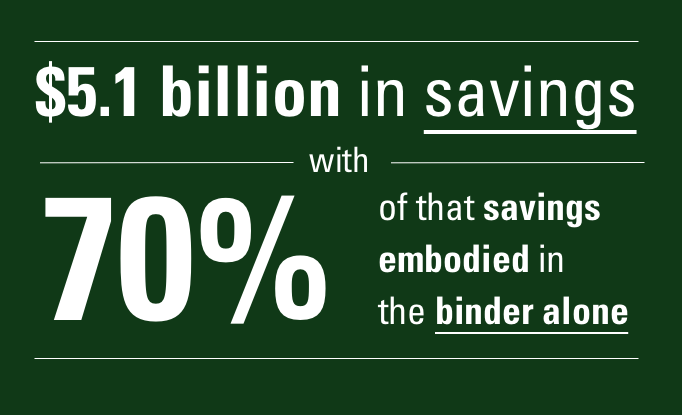

Increased performance and sustainability result in significant cost savings. According to NAPA, the savings from higher binder replacement significantly outweigh the cost of any extra testing that may be required. The total amount of asphalt and aggregate available on an annual basis can result in $5.1 billion in savings, with 70% of that savings embodied in the binder alone.

SigmaBond Checks All the Boxes

Using our SigmaBond modifier as a binder ups the ante for all the key benefits listed here. Because SigmaBond contains completely digested tire rubber, you can pack even more recycled materials into an asphalt hotmix. It’s the only terminal blend PG-TR and ARHM that routinely uses more than 15% RAP. SigmaBond also releases performance-enhancing qualities, such as resistance to cracking and fatigue, low-temperature improvement and reduced discoloration.

An independent study by the University of Nevada, Reno, correlated this performance improvement with a 10% to 25% reduction in construction cost per lane-kilometer when compared to conventional asphalt pavement. Learn about the science behind SigmaBond here.

We look forward to more studies and discussions around sustainable pavements and hope the asphalt industry continues on the path to reducing waste and building roads that last.